PDF: Cummins PT Pump installation Instructions

Removal

- Clean the exterior of the injection pump and mounting surfaces.

- Remove the electrical wire to the fuel shutdown valve.

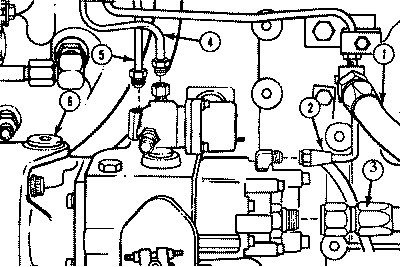

- Remove the fuel tubing and air tube:

- Fuel drain line from the T-block connection (1) if equipped

- Gear pump cooling drain (2)

- Gear pump suction line (3)

- Fuel supply to the injectors (4)

- AFC air supply tube (5)

- Tachometer cable (if used) (6)

- Remove the two fuel pump support bracket to cylinder block bracket mounting cap screws, if equipped.

- Remove the linkage from the throttle lever.

- Remove the four fuel pump mounting cap screws and the fuel pump.

- Remove the drive coupling spider.

Inspection

- Clean the gasket surfaces of the pump support and the compressor.

- Inspect the mounting surfaces for damage.

- Inspect the jaw coupling spider and the jaw coupling hub for damage or wear.

Installation

- Install the fuel pump drive coupling spider.

- Use a new gasket when installing the fuel pump.

- Install the four 12 point fuel pump mounting cap screws.

- Install the two fuel pump support bracket caps crews to the cylinder block bracket. Tighten the four fuel pump mounting caps crews. Torque Value: 47 n.m [35 ft-lb]

- Tighten the two support bracket to cylinder block cap screws, if equipped. Torque Value: 47 n.m [35 ft-lb]

- Install fuel drain from the T-block connection, if equipped (1)

- Install gear pump cooling drain (2)

- Install gear pump suction line (3)

- Install fuel supply to the injectors (4)

- Install AFC air supply tube, if equipped (5)

- Install Tachometer cable (if used) (6)

- Install the electric wire to the fuel shutoff valve. The wire connection nut must be clean and tight.

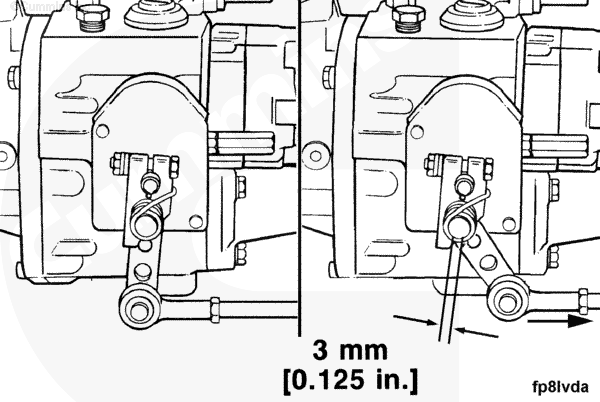

- Install throttle lever and linkage

- Check for full throttle travel

Priming and Starting

- Remove the plug from the top of the housing.

- Fill the housing with clean diesel fuel.

- Install the plug into the top of the housing. Torque Value: 27 n.m [239 in-lb]

- If the priming plug is hard to remove or the fuel pump is a VS type, remove the fuel supply hose to the gear pump.

- Fill the hose and gear pump with clean fuel.

- Install the fuel supply hose to the filter head.

We repair, rebuild and test Cummins PT pumps. Over the years, we have found engine serial numbers do not work for correctly identifying a PT pump. What works best are the numbers off the pump nameplate, the CPL and HP & RPM. Normally, we rebuild instead of selling rebuilt exchange pumps, due to the customization that has often been done. Cost varies depending on the fuel pump code (build list), and turnaround time varies from 3 to 14 days depending on the pump code and if we order any non-stock parts Next Day Air. Fill out the service form, or call us with the information off your pump.